Today, we would like to discuss why handbag factory need to charge sample fee when they developing samples for their clients.

Sample development is a time-consuming and labor-intensive development process which is different from the mass production procedure. During this stage, we require support from our sourcing dept., sample dept., design dept. and so on.

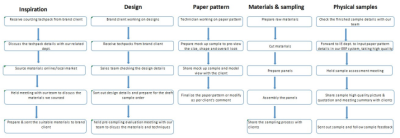

Here is our sample process for your checking:

From above sampling process, we can learn it’s not a easy thing to achieve a sample from idea to physical samples, we have to invest on below points:

- R&D cost

When we receive the inspiration file from our clients, our sourcing dept. need to source the suitable materials according to client’s design demand which will take about 2-7 days.

Once receive the techpack from our clients, we need to held meeting with our team to check if the design details and technique are workable and reasonable, then our technician will work on paper pattern according to the techpack, usually, a set of paper pattern requires our skilled technicians to spend approximately 1 to 2 days to complete.

Before producing the official sample, our technician will prepare a mock up sample for client to review the design details, if the clients have modification, they need to spend extra 1 day to modify the paper pattern.

- Labor cost

To developing a handbag sample, it requires multiple process such as cutting, edge painting, customize logo, sewing, assembly the panels and so on, the whole process will take about 3- 7days.

There are 15 sample technicians and 70 workers in our sample dept. who could help us to achieve the designs very quickly and nicely.

- Material cost

A handbag sample requires to use many kinds of raw material such as leather, lining, hardwares, reinforcement and so on.

At sampling stage, all materials also have their own MOQ, for example the leather’s MOQ is one skin which is about 20-30sf(cow hide leather), however, a medium size bag comsuption is about 5sf, if the client won’t use that skin of leather in the future development, we will have 15-25sf leather leftover.

If the materials need to customize color, for sampling qty, we have to pay for the surchage.

Actually, the actual sample cost is much more than the sample fee we charge as the leather wastage is bigger, the price of raw materials is higher, the labor cost is higher….

- Risk management

After we finished the samples, if the clients is not satisfied with the sample’s design/material and require to change design/material to remake; or the samples were cancelled since it didn’t be selected by thier top management……

Sample fee could help to cover the cost caused by these potential rish and reduce the loss due to order cancelled because of client change thier mind or cancel the styles.

- Double confirm client’s demand

The handbag design is complex and diverse, the designer may have many requirements on color, measurement, technique etc.Collecting sample fee could help to ensure the clients did have demand on sample development and reduce the loss due to client randomly change the sample design or cancel the development.

- Technical protection

The factory orientation determine their quality and cost, that means the same design but produced by different factory, their quality and cost will be different.

Before we developing the samples, we will check the target price with the client and use match technique and recommend suitable materials to make sure the cost could match with client’s target price.

The handbag factory charges a sample fee mainly to cover the costs of materials, labor and other expenses during the sample production process. At the same time, it aims to control potential risks and ensure that the customer’s requirements are clear and reasonable.

This is not only an industry practice but also a self-protection mechanism for the factory during the sample production stage.

For the customer, paying the sample fee is also a recognition of the factory’s investment, which helps both parties achieve better communication and understanding in the subsequent cooperation.

Fiedle, specialized in manufacturing leather bags/wallets for 24 years, offering OEM services for the international local top /second brands, we are warmly welcome you to visit us and develop handbags together.