Recycled leather is a man-made material created from leather scraps and fibers that are shredded and then bound together with synthetic or natural binders like polyurethane or latex. This process gives discarded leather a new life, resulting in a product with a leather-like appearance and texture that is used as a sustainable alternative to traditional leather.

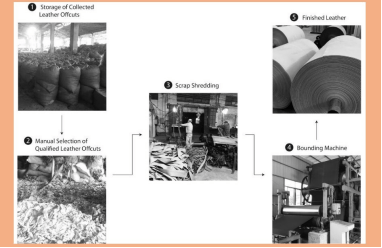

How It Is Made?

The production of recycled leather typically involves several key stages, utilizing waste from sources like furniture production, tanneries, and old leather products:

1.Collection and Sorting: Leather scraps are gathered and sorted to separate non leather parts (like zippers or hardware) and remove impurities

2.Shredding and Grinding:The sorted leather is shredded into fine fibers or granules.

3.Binding and Pressing: The fibers are mixed with a binding agent, often natural latex or water based polyurethanes, and pressed together using high pressure to create a strong, uniform sheet material. Some advanced methods use high-pressure water jets instead of chemical adhesives to fuse the fibers to a textile core.

4.Finishing: The resulting sheets are finished with color, texture, and coatings (e.g., a polyurethane layer) to mimic the look and feel of traditional leather and add durability.

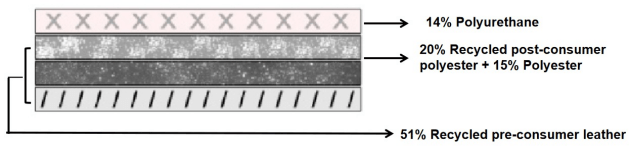

What is the composition?

For different items, the percentage of composition would be different. Here are the examples to share with you: 51% Recycled pre-consumer leather + 14% Polyurethane + 20% Recycled post-consumer polyester + 15% Polyester.

What is the advantage to use recycle leaher?

1.Waste Reduction: Recycled leather is made from discarded leather scraps, offcuts, and used products that would otherwise end up in landfills, where they can take decades to decompose and potentially release harmful chemicals.

2.Conservation of Natural Resources: By utilizing existing materials, the need for new animal hides and the resource-intensive processes of livestock farming and tanning (which consume large amounts of water and land) is reduced.

3.Lower Environmental Footprint: The production process generally requires less energy, water, and fewer harsh chemicals compared to virgin leather manufacturing, resulting in a lower carbon footprint and reduced pollution.

4.Support for a Circular Economy: Choosing recycled leather supports a circular economy, where materials are kept in use for longer, minimizing waste and promoting sustainable production cycles.

Is recycle leather good for making bag?

Recycle leather is an excellent material for making bags because it performs well in terms of softness, durability, sustainability and aesthetics, and is increasingly popular among consumers.

Many luxury brands have already adopted this new type of material. Therefore, for brands and companies that focus on both fashion and functionality, recycle leather is a great choice.

Conclusion

Recycle leather, as an environmentally friendly, durable and beautiful material, is highly suitable for making fashionable bags and has broad application prospects. However, at present, it also faces challenges, such as high production costs, relatively expensive product prices, and geographical restrictions on raw material supply.

In the future, with the continuous advancement of technology and the gradual development of the industry, apple leather is expected to occupy a more important position in the fashion market.

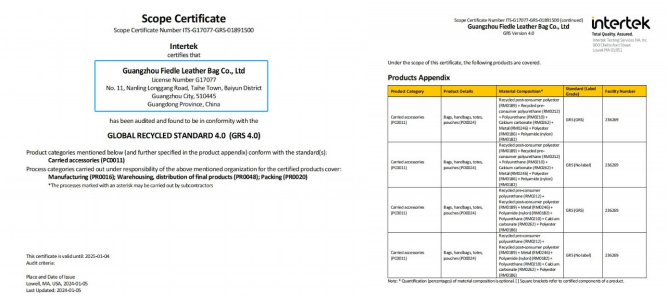

If you are running or planning to start a bag business and are considering using recycle leather to create your own brand of bags, please feel free to contact Fiedle. Let’s work together to create miracles for your bag business. Fiedle is a leather bag manufacturer based in Guangzhou and we are a GRS/RCS certified recycled bag factory, that means we could open TC for related bags for you.

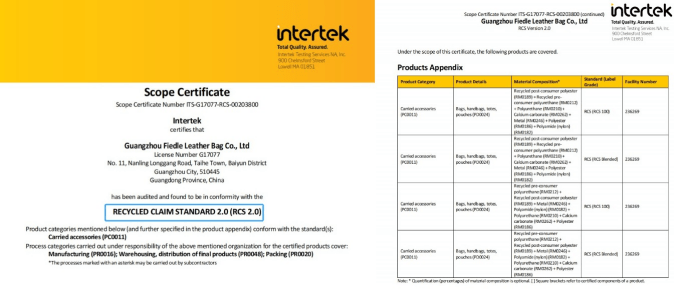

Here are the GRS/RCS certification for your reference:

1) GRS

2) RCS certification