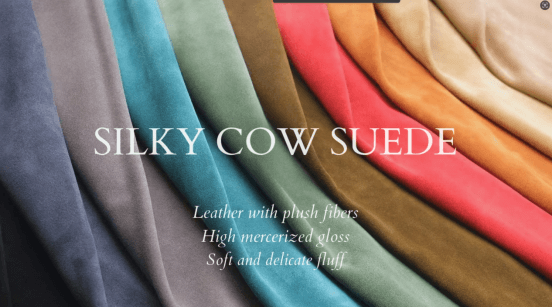

Suede captivates with its tactile warmth and sophisticated, muted glow—a key texture for creating depth in modern collections. Yet, its very beautiful, born from a surface of delicate fibers, introduces unique considerations for durability and color performance.

Suede leather, also referred to as simply “suede,” is the bottom layer of a cow hide.

After a cow hide is tanned, the hide is split into a top and bottom layer. The top layer will become full and top grain leather (our specialty) and is most often used for upholstery. The bottom layer will become suede or finished into a variety of leather products often referred to as “genuine leather.”

At Fiedle, we believe that true luxury lies not in avoiding a material’s character, but in mastering it through intelligent design and precise engineering. This guide delves beyond the surface, providing the essential knowledge and practical strategies needed to harness suede’s appeal while ensuring product integrity and customer satisfaction. Let’s transform its natural nuances from potential challenges into your brand’s signature of thoughtful craftsmanship.

1.Characteristic

Suede cow leather is with flurry hand feeling cause its surface is with multiple tiny fibers. When rubbing on the suede leather, these fibers will drop off so these fibers will transfer to the rubbing stuff—this phenomenon called color transfer/color faded.

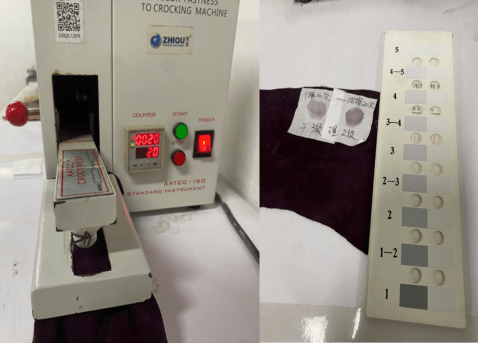

Due to this characteristics, suede leather color fastness is different to normal smooth leather. For industrial standard, its color fastness is-2.5-3 grade dry rubbing and 2-2.5 grade wet rubbing.

Color transferred of suede leather is more obvious in dark color tones like black, brown, tan and some vivid color like red, fuchsia and royal blue.

2.Causes of Color Variation

Color consistency in suede leather is influenced by several factors inherent to its natural properties:

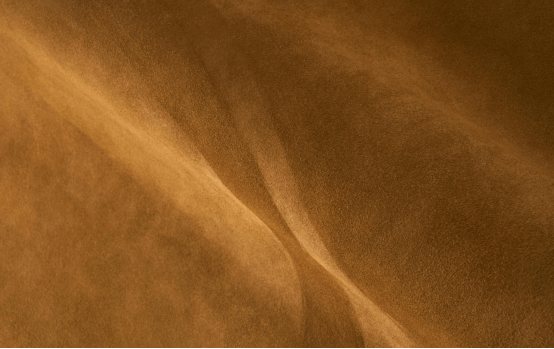

Comparison with smooth leather: The fibrous structure of suede reflects and absorbs light differently, often making color variations more visually apparent.

Variation within a single hide: Differences in fiber density and tightness across various parts of the same hide lead to uneven dye absorption:

Back/hip area: Tighter fibers result in weaker dye absorption and a relatively lighter color.

Belly/neck area: Looser fibers absorb dye more readily, typically producing a deeper color.

Impact of finishing processes: The post-dye washing process, used to enhance color fastness, can affect the final shade. Longer washing times may lead to slight lightening of the color.

Usually, we will cut the same color tone in 1 set on the same bag, so to better control the color variation of the suede leather on handbag.

3. Reasons for Uneven Nap Length

The uniformity of the nap is a natural characteristic of suede leather, primarily influenced by:

Geographic origin and raw material: Cattle breed and growth conditions (e.g., climate, rearing cycle) in different regions directly affect the thickness and density of the raw hide fibers, which in turn determine the nap’s fineness and length.

Hide section variation: On the same hide, the back/hip area has dense fibers, leading to a finer, shorter nap; the belly/neck area has looser fibers, resulting in a coarser, longer nap.

Processing techniques: Multiple washing (re-washing), used to improve quality, can also make the nap appear fuller or longer.

Longer nap on belly/neck area

Shorter nap on back/hip area

4.Color Fastness Details and Risks

Grade categories: Suede leather is generally classified into three grades, with increasing color fastness:

Standard suede: Lowest color fastness, high risk of color transfer.

Silky and high-silky suede: Treated with special processes to significantly improve color fastness, though color transfer cannot be entirely eliminated.

Acceptable standard reference: Dry rubbing Grade 2.5–3 and wet rubbing Grade 2–2.5 are generally considered acceptable.

Key process – washing: Washing is essential for removing excess surface dye and enhancing color fastness.

Insufficient washing: Produces a smooth surface with short nap but retains excess dye, leading to poor color fastness (as low as Grade 1) and high transfer risk.

Adequate washing: More washing cycles remove surface dye more thoroughly, improving color fastness (up to Grade 2.5–3) and significantly reducing transfer risk.

Usage risk note: Color fastness below Grade 2 indicates a potential transfer hazard. For instance, leather with Grade 1 color fastness rubbing against light-colored clothing (e.g., a white T-shirt) for an extended period is highly likely to cause staining.

5.Practical Recommendations for Product Development

In this case, when developing suede leather handbag, we usually recommend brand customers to use regular leather on the back panels and on the bottom part of the shoulder strap, so to avoid direct touching with clothing when customers carrying, and to prevent the color transfer to the clothing for further quality complaint.

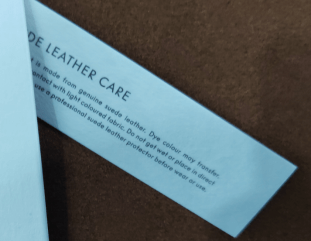

Besides, we will also suggest brand customers to have a notice/disclaimer hand tag on their products, to remind the characteristic of suede leather and how to avoid wearing light color clothing when carrying suede leather handbag.

6.How to Clean Suede Material

It is important to note that suede leather is a porous material, and requires some simple care and protection to keep it looking new. A suede protectant is always recommended, and can be applied before use to help prevent staining. We prefer non-aerosol, solvent-free products that can be sprayed evenly onto the surface, like Uniter’s Eco-Protector. Which protects against oil, water, and alcohol based stains. When using any protectant, be sure to test a small, inconspicuous spot before applying to a large area.

If needed, suede can be spot cleaned with a soft, moist, lint-free cloth, or suede friendly sponge- using either water, or a suitable cleaner. It is imperative that the cleaner, and cloth or sponge, are safe for suede.

You may find that a damp cloth or sponge temporarily darkens your suede, don’t worry! As long as appropriate products were used, your suede should return to its original color once dried. A soft, suede-safe leather brush can also help restore the look and feel of your suede, especially after cleaning.

At Fiedle, we combine extensive expertise in suede leather craftsmanship with a forward-looking vision for AW26 trends. As your premier choice for developing premium suede bags, we invite you to contact our team to discuss your project.