Welcome to our leather goods manufacturing facility. Design, production, and quality control are integrated under one roof,

allowing us to maintain stable quality and reliable manufacturing for global customers.

Raw Materials Management

Stable raw material suppliers are the foundation of making sure good quality.

Our leather, hardware, linings, and accessories are sourced from long-term partners who provide consistent quality, competitive pricing, and reliable delivery.

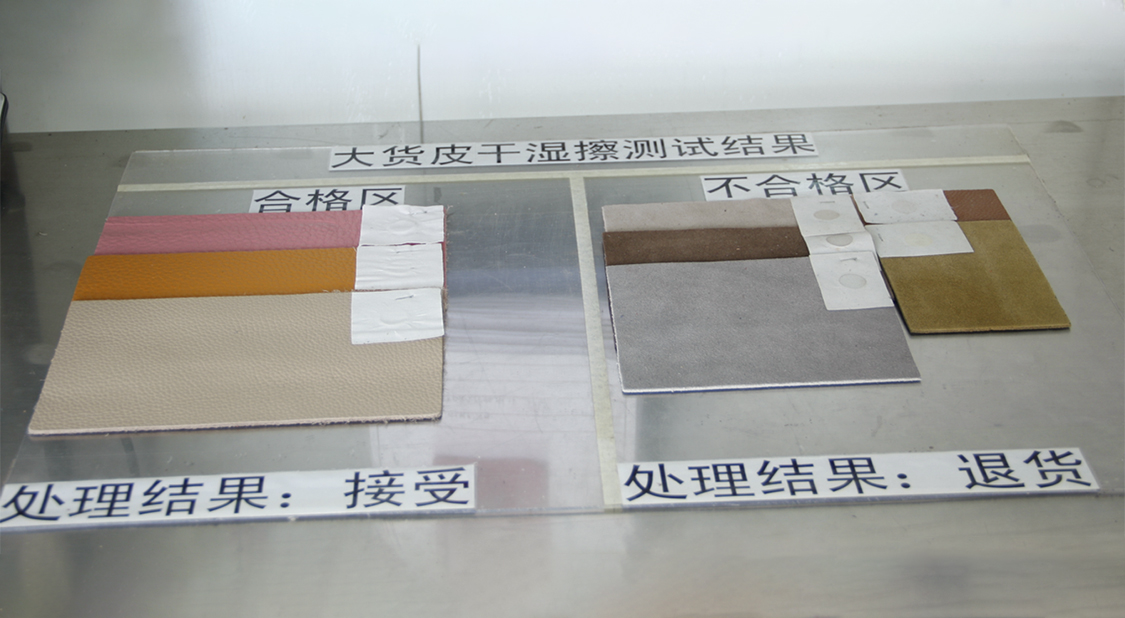

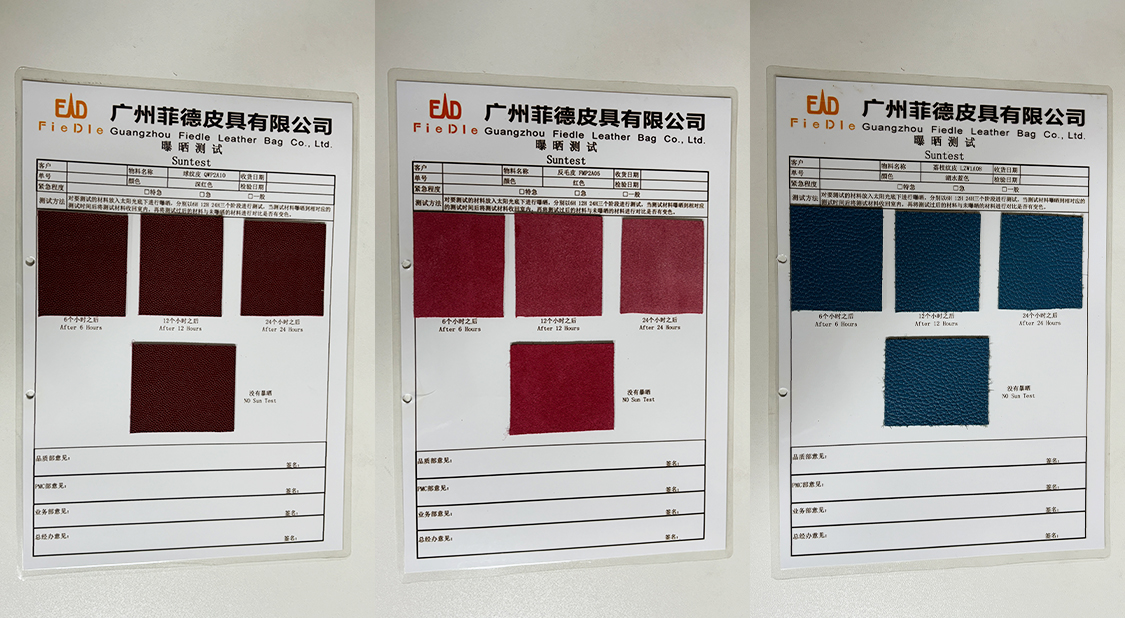

All materials undergo 100% inspection before mass production to ensure quality and production efficiency.

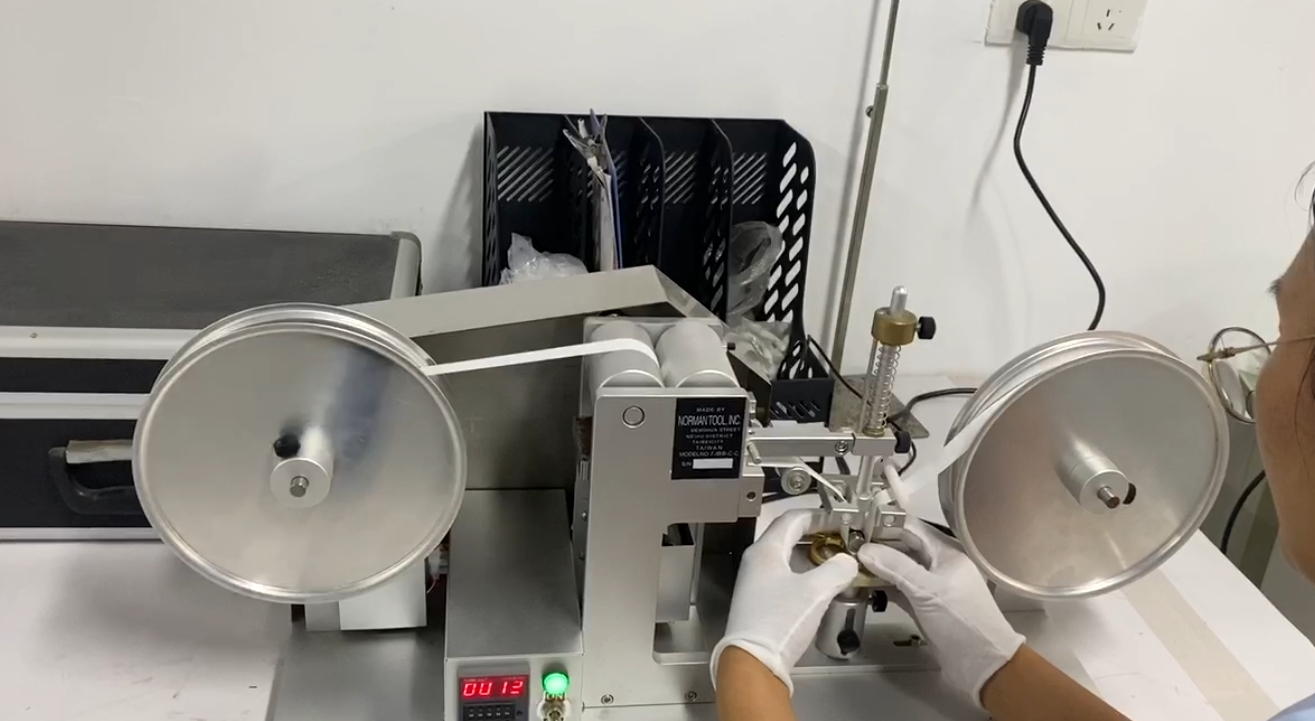

Leather inspection

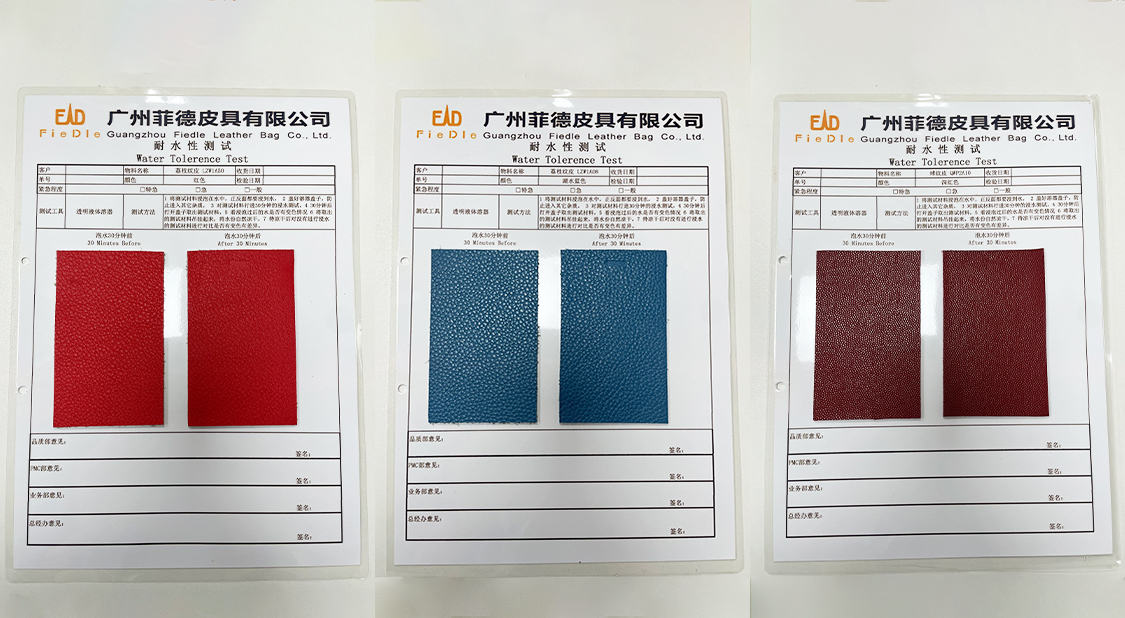

Fiedle procures its premium leather exclusively from LWG certified tanneries. As the first step in our production, each hide is subject to meticulous inspection for texture, color consistency, and durability prior to cutting.

Hardware inspection

For all hardware/related materials, our IQC will do 100% inspection. Only the qualified materials could be passed into our production line.

Manufacturing Process

All key manufacturing processes are completed in-house. Standardized procedures are

followed at each stage to ensure stable output and consistent workmanship for OEM and ODM projects.

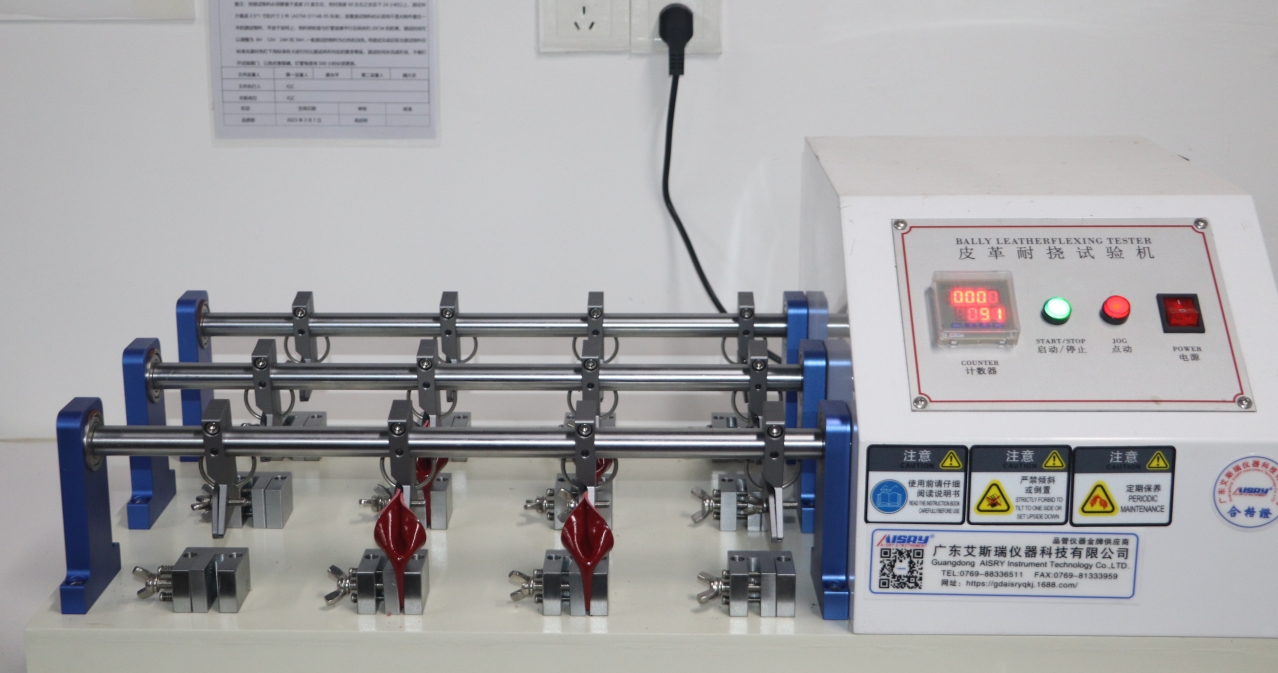

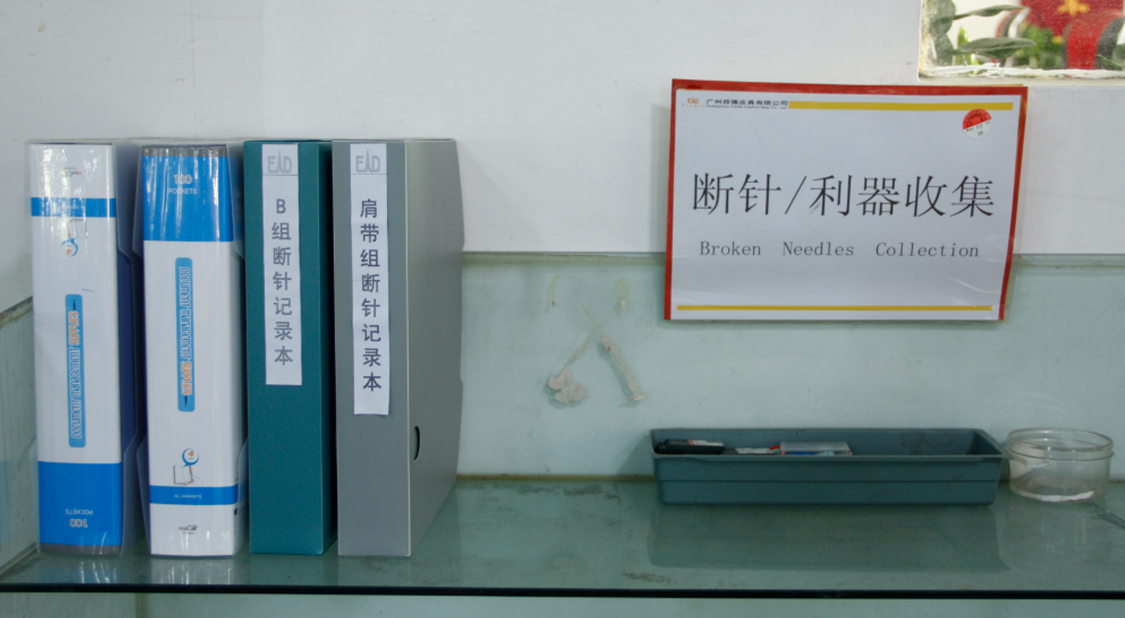

Quality Control System

Quality is not checked only at the end. It is controlled throughout the entire production process

— from incoming materials to final shipment.

- Incoming Quality Control (IQC)

- In-Process Quality Control (IPQC)

- Final Inspection & Shipment Control

This is part of our strict quality control system, which is implemented at every step of the process, including final shipment checks.

Packing & Shipment

Preparation

Before shipment, all finished products undergo 100% final inspection. Additional controls are applied to ensure safety during storage and long-distance transportation.